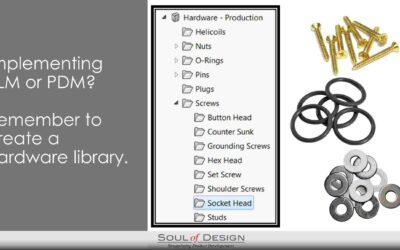

Product Data Management (PDM) systems, like Dassault’s Enterprise PDM, are effective tools at managing the product development process, however, there are numerous stories of PDM systems disappointing users and not providing the anticipated productivity gains.

PDM systems are process management tools, so to achieve the anticipated productivity gains, the processes being mapped onto the PDM systems need to be effective and efficient, otherwise regardless of the PDM system, the productivity gains cannot be realized.

Several companies I have worked with, began setting up PDM before understanding their processes, resulting in an ad-hoc setup approach that was ever-changing and resulted in a non-intuitive, disjointed process that ultimately frustrated users and failed to realize real productivity gains.

So before implementing a PDM system, evaluate the effectiveness of the existing processes.

Things to consider are:

- Are the processes documented and available for easy reference by the users?

- Are the processes fully mapped out in an easy-to-understand flow chart?

- Do the processes meet industry standards?

If no is answered for any of the above questions, before implementing PDM, consider reviewing, refining and fully documenting the processes.

Processes that are understood and documented before being mapped to PDM allow for a simpler, top-down, and relatively quick setup of PDM, achieving real productivity gains.

0 Comments